Feature:

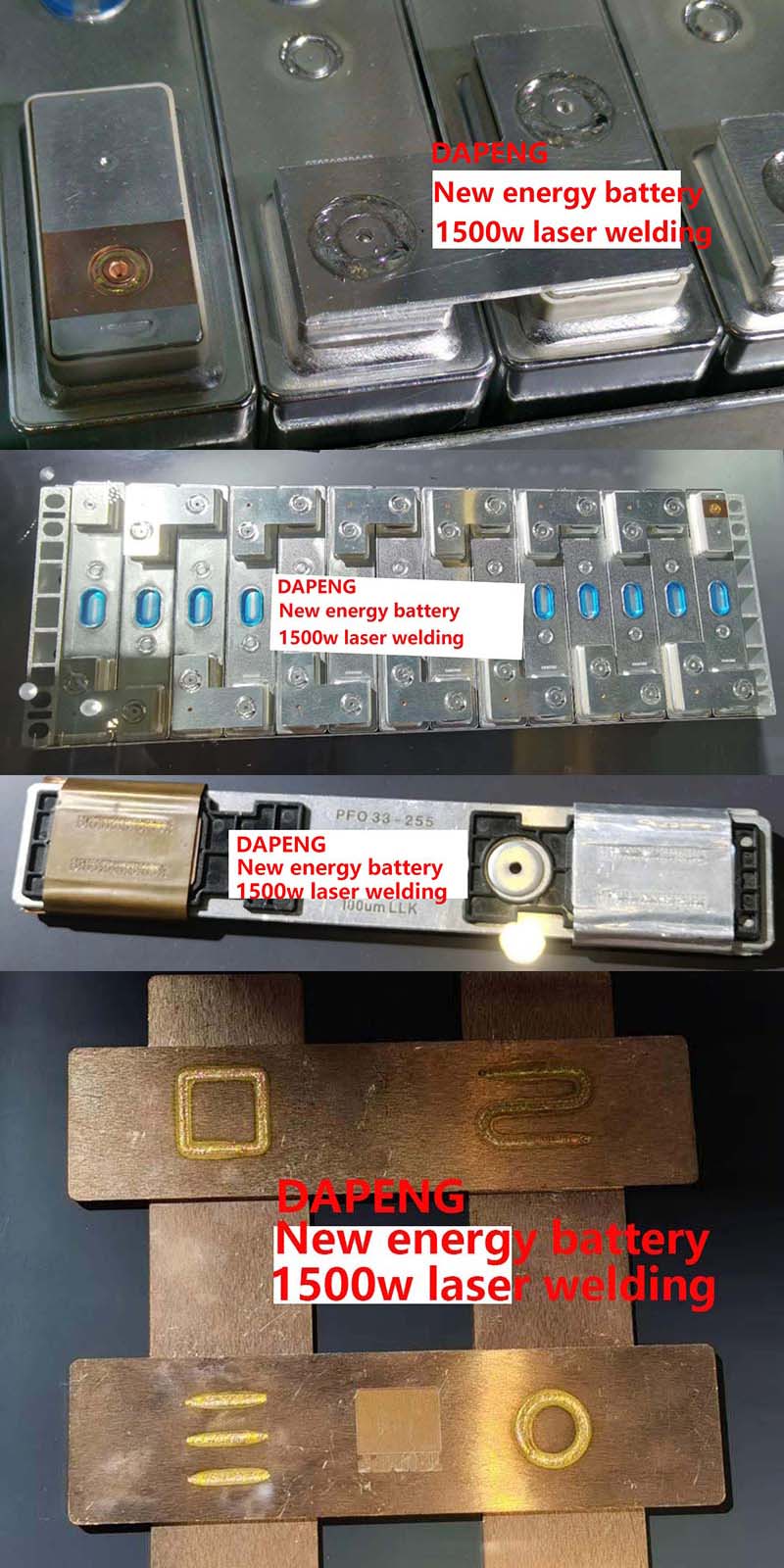

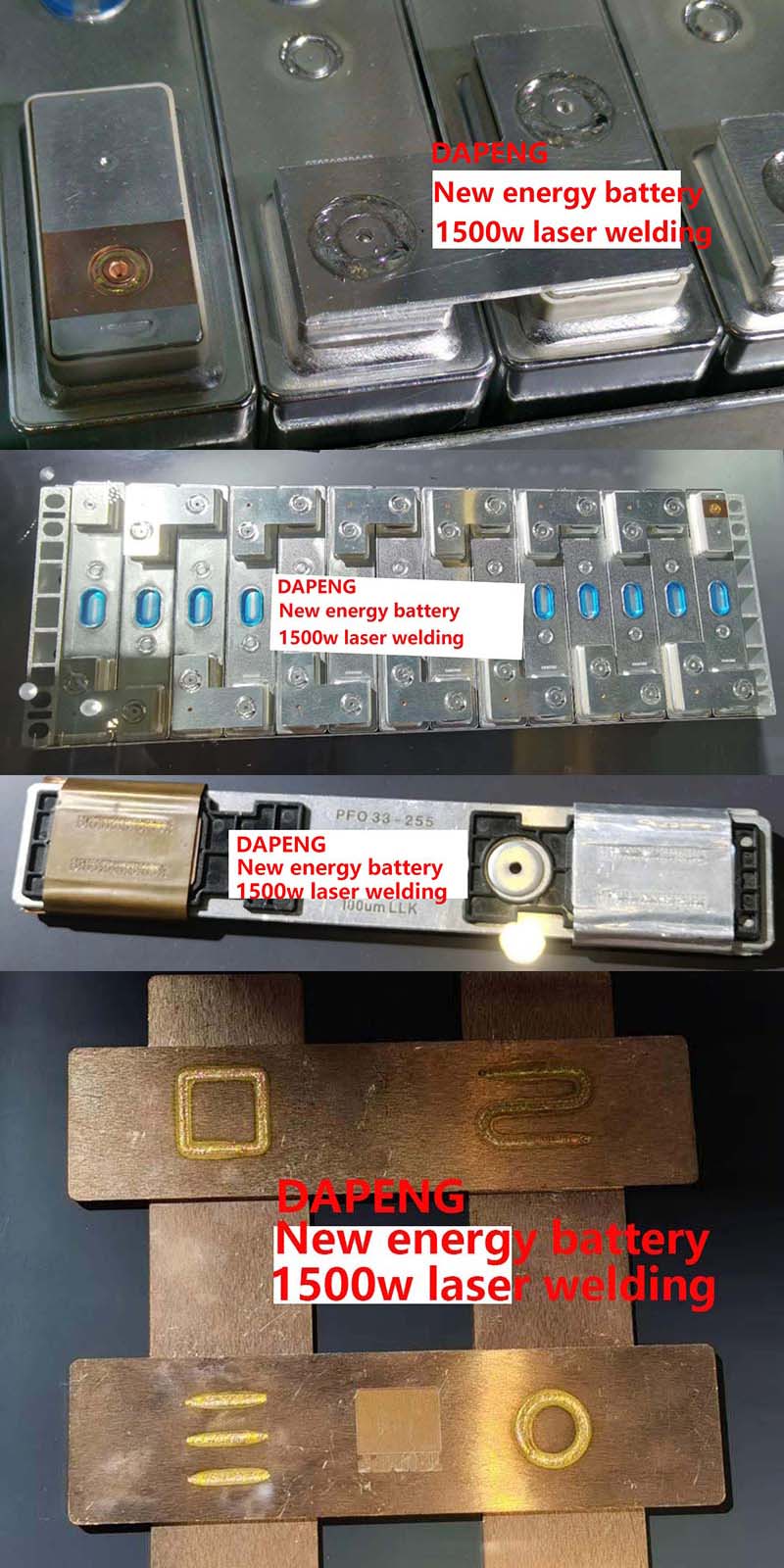

1.The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

2.High cooling rate, which can weld fine weld structure and good joint performance.

3.Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

4.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

5.No consumables, small size, flexible processing, low operating and maintenance costs.

6.The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

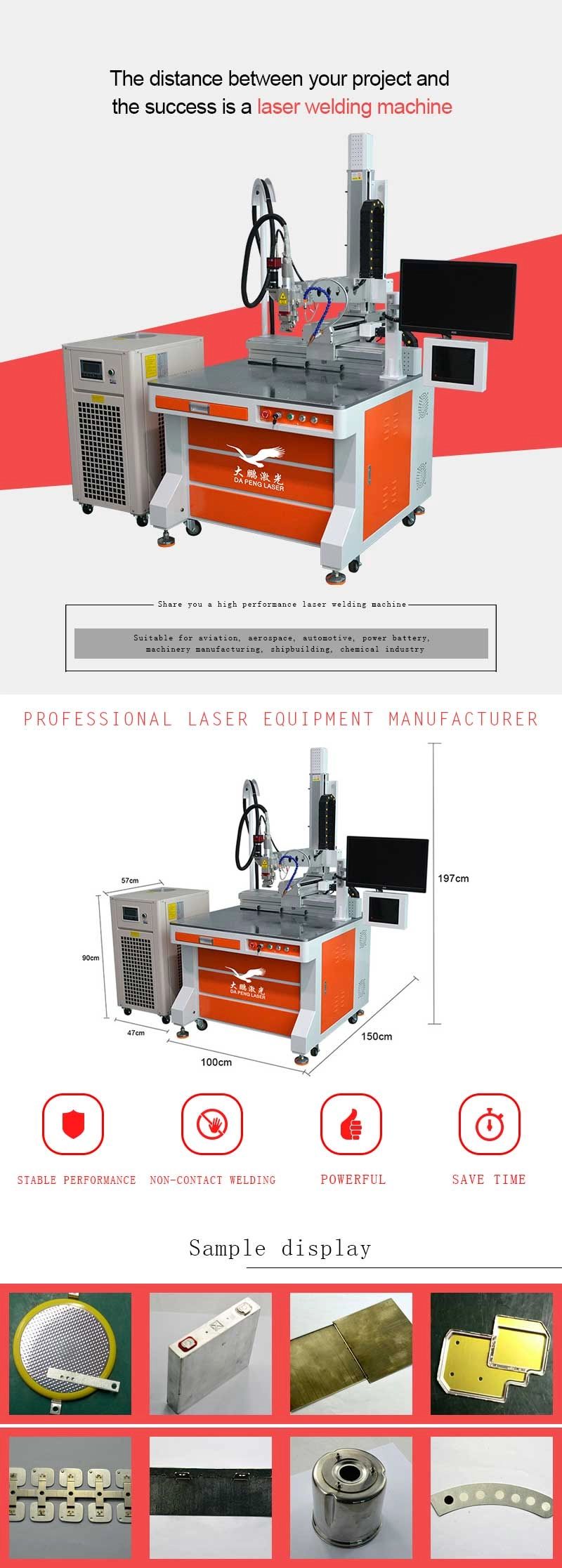

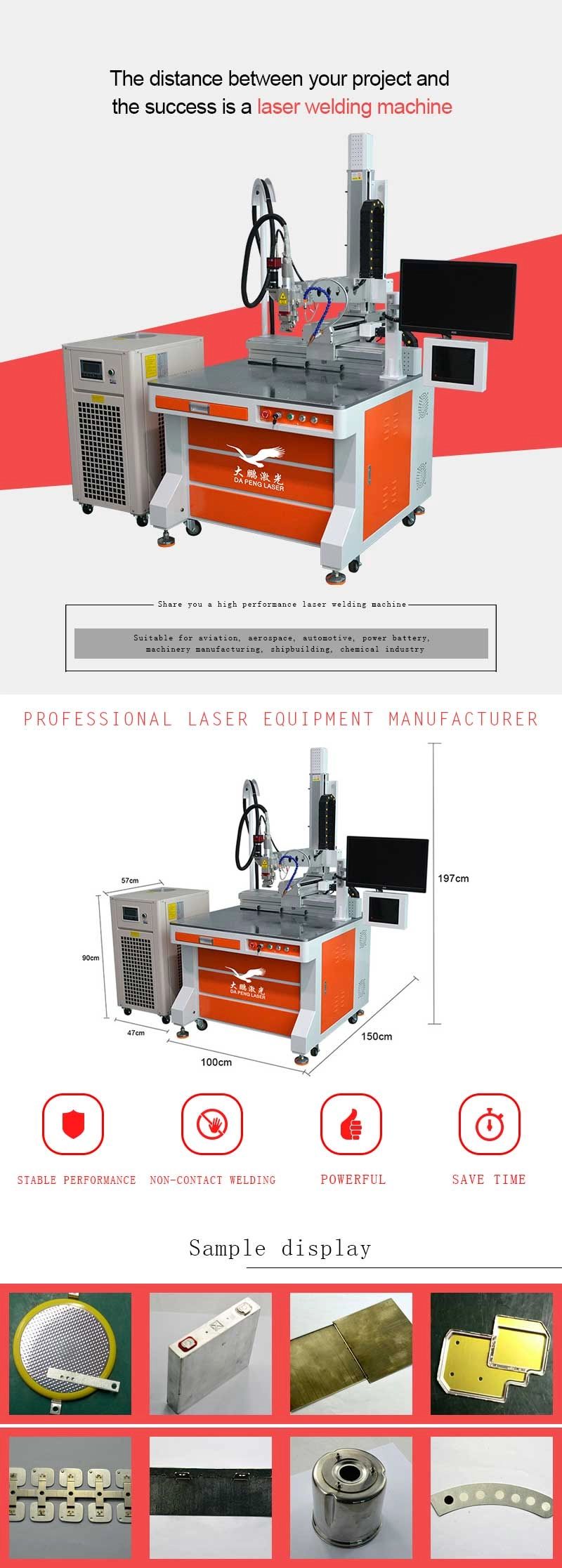

Application:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industries.

Specification:

|

Power |

1500W/2000W/3000W |

|

Laser wavelength |

1070nm |

|

Output power stability |

<3% |

|

Frequency |

0.5Hz-100KHz |

|

Adjustable power range |

10-100% |

|

Beam quality |

1.1 |

|

Output fiber length |

10m |

|

Cooling method |

Chiller |

|

Laser source |

Raycus/MAX |

|

Welding head |

Wobble welding head |

|

Welding CNC system |

C6 |

|

CCD camera |

20 times magnification |

|

Motor |

Servo motor |

|

Dimensions |

100cm*100cm*172cm |

|

Weight |

300kg |

Videos: www.facebook.com/dapenglaser www.linkedin.com/in/dapenglaser

Fiber laser source laser welding machine https://youtu.be/j-UnubCM3OU

sales@dapeng-laser.com Whatsapp:+8618565695703 Contact KENDY and send you machine teaching videos and manual for free.

sales@dapeng-laser.com Whatsapp:+8618565695703 Contact KENDY and send you machine teaching videos and manual for free.