High speed, high efficiency, deep, small deformation, small heat effect area, high welding quality, pollution free welding spot.

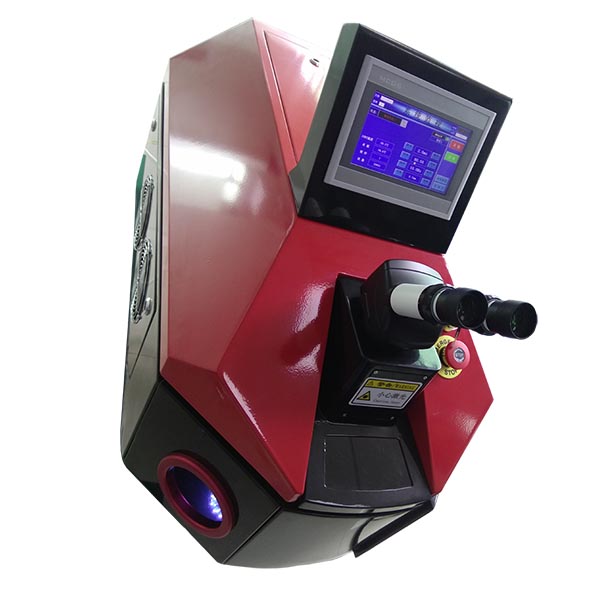

Jewelry laser welder is mainly used in perforating and spot welding of white gold, platinum, carbon steel, stainless steel. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool.

Features:

1. Good performance of corrosion resistant and high temperature resistant. The life of xenon lamp is: Max 5 million times.

2. Human-based design accords with ergonomics, avoiding fatigue after long time working.

3. Widely used in jewelry accessories, electronic components, glasses clocks and watches, hardware, precision equipment, medical equipment, auto parts, gifts and crafts, etc.

Specification:

|

Laser wavelength |

1064nm |

|

Frequency |

0.1-20Hz |

|

Pulse width |

0.5-15ms |

|

Spot size |

0.1-3mm |

|

Power require |

Single phase 220VAC 50Hz |

|

Display Positioning System |

Microscope (CCD Optional) |

|

Cooling system |

Water cooling |

|

Consumables |

Xenon lamp, protective lens |

|

Usage environment |

Clean,no shaking |

Standard accessories:

1.Laser power supply, 1 set

2.Laser crystal rod, 1set

3.Focus mirror & Beam expander, 1 set

4.Ceramic converging cavity, 1set

5.Microscope x10, 1set

6.Xenon lamp, 1set

7.Protective lens, 1set

8.Cooling system, 1set

9.Foot switch, 1 set